Chemical Adsorbents Zeolite 4A Molecular Sieve Desiccant For Truck Pneumatic Brake

Product Description of 4A Molecular Sieve Desiccant

Molecular sieves for automotive brakes are mainly used for drying of pneumatic braking systems such as automobiles, heavy trucks, trains and boats, including the removal of moisture in automobile air conditioning systems and air brake braking systems. Moisture in the pneumatic system will corrode the pipeline and affect the braking effect, and even lead to the failure of the braking system in severe cases. Therefore, it is necessary to pay attention to regularly draining the accumulated water in the system and to replace the molecular sieve dryer regularly. If any problems are found, replace it in time. Molecular sieves for automobile brakes produced by Lvneng LTD have the characteristics of good chemical compatibility, high adsorption capacity, high crushing strength, low dust degree, and high dry and wet wear capacity.

Technical Description

In the motor vehicle air brake system, due to the frequent changes of the compressed air, the air temperature drops, causing water accumulation in the brake air path, which in turn causes the metal components in the brake system to corrode, resulting in cracks in the rubber seals and dispersion of lubricating grease. Failure, pipeline blockage and other failures, seriously affect the safety of driving, in order to solve this problem.

In recent years, the use of compressed air drying devices, the compressed air dryer, has been gradually promoted at home and abroad. It is installed in the vehicle brake air circuit, and the dryer is filled with air-drying molecular sieves to dry the compressed air. Efficacy and safety of air brake systems.

The special desiccant for the vehicle brake air circuit can be used as the compressed air desiccant in the motor vehicle air brake system to protect the brake air circuit and avoid the occurrence of safety accidents.

This product not only absorbs the moisture in the compressed air, but also makes the compressed air of the desiccant in the regeneration air storage cylinder pass through the desiccant in the reverse direction, taking away the moisture adsorbed on the surface of the desiccant and discharging into Atmosphere for regeneration.

Application

Technical Specification of 4A Molecular Sieve Desiccant

| Item |

Unit |

8*12 Mesh |

4*8 Mesh |

| Bead Size |

mm |

1.6-2.5 |

3.0-5.0 |

| Bulk Density |

g/ml ≥ |

0.72 |

0.70 |

| Equilibrium Water Capacity @ 25°c |

wt% ≥ |

22 |

22 |

| Equilibrium Methanol Capacity |

wt% ≥ |

15 |

15 |

| Heat of Adsorption |

BTU/lb of H2O |

1800 |

1800 |

|

Crush strength

|

Point Contact |

N ≥ |

35 |

85 |

| Variation Coefficient |

- |

0.3 |

0.3 |

| Attrition Rate |

wt% ≤ |

0.1 |

0.1 |

| Size Qualification |

% ≥ |

98 |

98 |

| Package Moisture |

wt% ≤ |

1.5 |

1.5 |

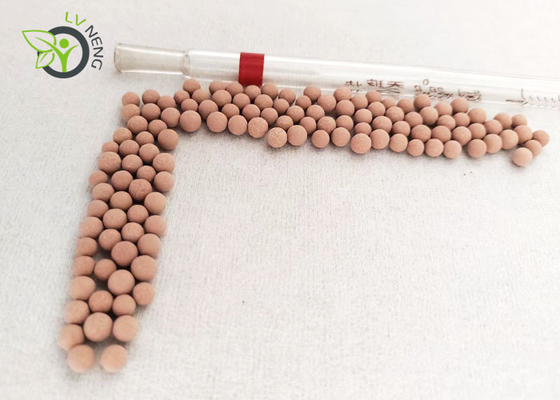

Display of 4A Molecular Sieve Desiccant

Package of 4A Molecular Sieve Desiccant

Factory View of 4A Molecular Sieve Desiccant

Attention of 4A Molecular Sieve Desiccant

- The product cannot be exposed in the open air & should be stored in dry condition with air-proof bag.

- It should be regenerated after a certain period of adsorption. The appropriate regenerated temperature would be better below 350°C.

FAQ of 4A Molecular Sieve Desiccant

Q: Could we send a free sample for reference?

A: Yes, of course.

Q: What about the price and MOQ?

A: We promise a competitive price with top quality, & accept both mass and small quantity order.

Q: What is the lead time?

A: Within 15 days after received payment.

Q: Payment term?

A: 100% TT in advance. or 30% TT deposit & balance before shipment.

Q: How to solve problems after sales?

A: Take photos of the problems. After confirmed, we will make a satisfying solution for you within 3 days.

For More information please contact us. It's our pleasure to serve you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!